CNC Torna turlari Dvigatel uchun zanglamaydigan po'lat / alyuminiy moslashuvchan mufta

Egri jag'li muftalar

Egri jag'li muftalar ko'plab ilovalarda qo'llanilishi mumkin va universal mufta sifatida xizmat qiladi.Egri jag'ning asosiy dizayni ixcham dizaynda yuqori tork sig'imini ta'minlaydi.Egri tish kattaroq aloqa maydoniga ega, bu unga yuqori moment sig'imini beradi va chekka bosimini kamaytiradi.U eksenel, radial va burchakli milning noto'g'ri hizalanishiga mos keladi.

Hublar turli xil materiallardan ishlab chiqariladi: alyuminiy, kulrang, temir, po'lat, sinterlangan po'lat va zanglamaydigan po'lat.O'rgimchak elementlari Urethane & Hytrel-da turli xil durometr variantlarida mavjud.O'rgimchaklar oddiy ish tsikli sharoitida zarba yukini o'z ichiga olgan og'ir ish tsikllarini bajarishi va tizimdagi burilish tebranishlarini minimallashtirishi mumkin.

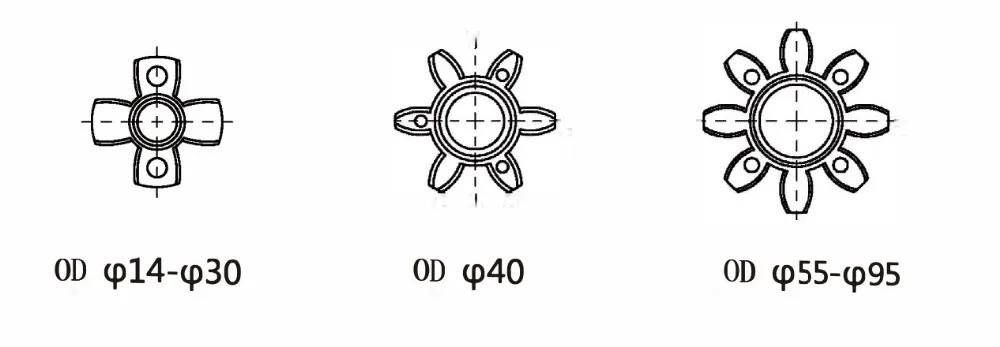

| Model | Teshik o'lchami (mm) | Nominal moment (Nm) | Maksimal moment (Nm) | Maksimal tezlik | Tashqi diametri (mm) | Uzunlik (mm) | Teshik tolerantligi (mm) |

| HS -TCN-14C | 3~7 | 0,7 | 1.4 | 45000 | 14 | 22 | +0,6~0 |

| HS-TCN-20C-R | 4~11 | 1.8 | 3.6 | 31000 | 20 | 30 | +0,8~0 |

| HS-TCN-30C-R | 6~16 | 4 | 8 | 21000 | 30 | 35 | +1,0~0 |

| HS-TCN-40C-R | 8~28 | 4.9 | 9.8 | 15000 | 40 | 66 | +1,2~0 |

| HS-TCN-55C-R | 9,5~32 | 17 | 34 | 11000 | 55 | 78 | +1,4~0 |

| HS-TCN-65C-R | 12,7 ~ 38,1 | 46 | 92 | 9000 | 65 | 90 | +1,5~0 |

O'rgimchakning xususiyatlari

Egri jag'ning muftasi ikkita metall uyasi va elastomerik "o'rgimchak" elementini o'z ichiga oladi.O'rgimchaklar mavjud

turli qattiqlik durometrlari, ularning har biri o'z rangi bilan osongina aniqlanadi.

| Qattiqlik | Rang | Material | Harorat diapazoni | Ilovalar |

| 80 Shore A | Moviy | Poliuretan | -50 ~+80 .C | Ajoyib damping |

| 92 Shore A | Sariq | Poliuretan | -40~+90 .C | O'rtacha damping, umumiy ilovalar |

| 98 Shore A | Qizil | Poliuretan | -30 ~+90 .C | Yuqori momentli ilovalar |

| 64 Shore D | Yashil | Poliuretan | -50 ~+120 .C | Yuqori moment, yuqori harorat |

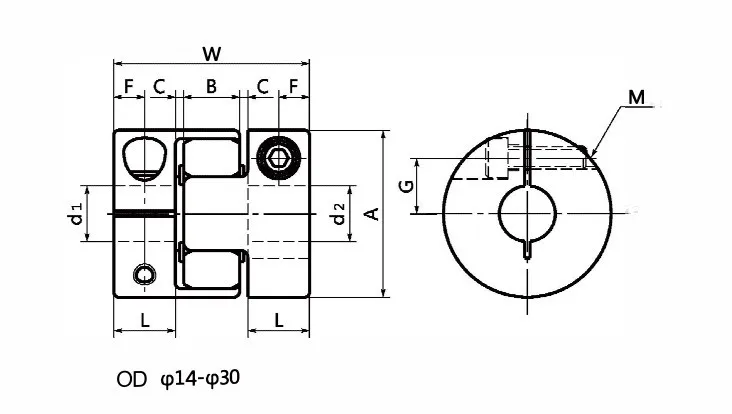

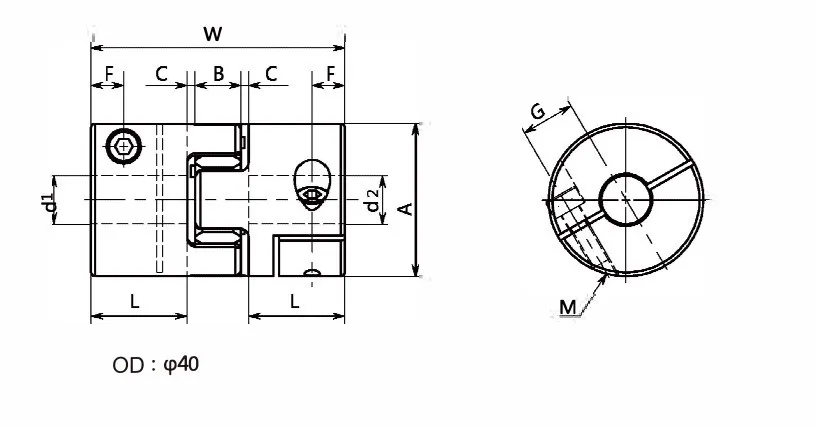

Bog'lanish o'lchovi ma'lumotlari

| A | L | W | B | C | F | G | M |

| 14 | 7 | 22 | 6 | 1 | 3.5 | 4/5 | M2/M1.6 |

| 20 | 10 | 30 | 8 | 1 | 5 | 6,5/7,5 | M2,5/M2 |

| 30 | 11 | 35 | 10 | 1.5 | 8.5 | 10/11 | M4/M3 |

| A | L | W | B | C | F | G | M |

| 40 | 25 | 66 | 12 | 2 | 8.5 | 14/15.75 | M5/M4 |

| A | L | W | B | C | F | G | M |

| 55 | 30 | 78 | 14 | 2 | 10.5 | 20/21 | M6/M5 |

| 60 | 35 | 90 | 15 | 2.5 | 13 | 24/25 | M8/M6 |